Gary Klaner's redesigned kitchen at the centre of the grand surroundings of the Landmark London offers a smoother way of catering for the hotel's many dining options, from breakfast to afternoon tea, as well as the cooler environment of induction. Lisa Jenkins reports

The kitchen of executive chef Gary Klaner, located on the ground floor of the Landmark London, could be considered the heart of the hotel. The building dates back to 1899 when, according to the hotel's history books, rooms cost a mere three-and-sixpence a night (roughly £14 today).

The hotel was designed around a vast courtyard, now known as the Winter Garden, which allowed light and air into the building. The Winter Garden restaurant is just one of many dining areas requiring the services of Klaner and his brigade. There is also the Great Central Bar & Restaurant, the Mirror Bar and the Garden Terrace, room service, afternoon teas, Champagne brunches and many private dinners and parties in the Grand Ballroom, the Marble Ballroom, the Drawing Room, the Empire Room, the Champagne Room, the Tower suite and four meeting rooms.

The hotel, which was bought by the Lancaster London Hotel Company in 1995 and renamed the Landmark London, became a member of the Leading Hotels of the World in 2008.

Klaner started the process of finding a consultant to refurbish the Landmark's kitchen in 2016. "I contacted Stephen Arnold [of kitchen design consultancy Humble Arnold] at the early stages of the project, but it took us two years to actually get it started," says Klaner. "The initial designs and drawings took a year."

The brief was simple, says Klaner: to design a kitchen with quality equipment that would last for 15-20 years. He also required the kitchen to be energy efficient and for the overall temperature to be reduced for the benefit of his staff. In addition, there was a specific requirement for a bespoke breakfast section.

There are 62 people in the brigade, with 30 kitchen porters and two senior sous chefs.

Oliver Tuff, project manager at Berkeley Projects, who took on the role of installation and fabrication, was told the latter had to be robust. The entire kitchen was constructed using highly specified material and a premium build quality. For example, each counter was made with rolled edges at the back of the unit to make them easier to clean and therefore more hygienic.

"The Athanor cooking suite was chosen for its robustness," says Klaner. "But I also liked the flexibility of design and that the service package for the suite is based in the UK."

Oliver Tuff, project manager of Berkeley Projects, says of winning the contract: "We like to work with a very hands-on project management style and only take on enough work so that we can be on site and manage projects properly.

"There was an eight-week build turnaround, but we completed the installation of the Athanor cooking suite in two and a half weeks, including all the fabrication."

A project of this size and complexity required intricate planning, and the Athanor suite was delivered at 4am to avoid blocking access routes and causing disruption to hotel guests during peak hours.

"Gary was very happy with the finished kitchen," confirms Tuff. "And we have already taken some of our other clients to the Landmark as a showcase of our work."

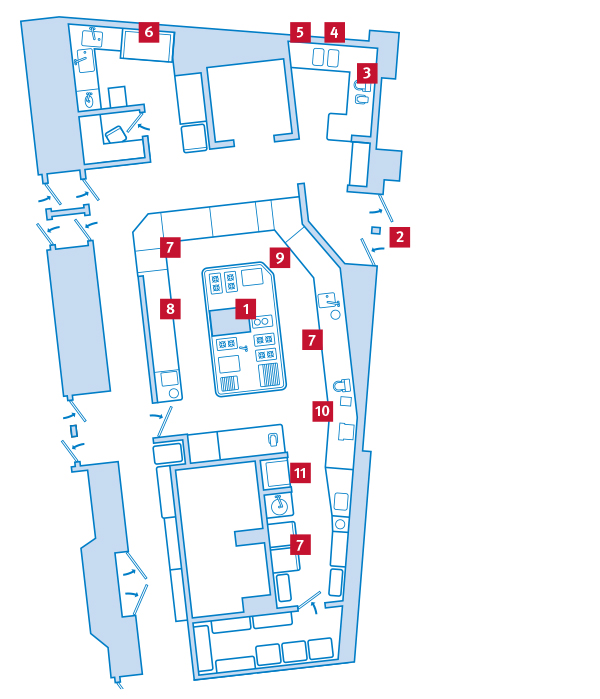

The Winter Garden kitchen

The island suite(1) has an overall footprint of 3800mm x 2100mm, constructed around a central pillar. The suite is split into three sections and can be operated from all sides. The main section, aligned with the hot pass, incorporates two twin 5KW induction hobs, a single 4KW plaque Athanor plancha, hot holding drawers and a large salamander grill.

The end section is designed to help support the busy breakfast service in the Winter Garden restaurant. The hot holding drawers are used for protein and carbohydrate breakfast items, while the induction units are for cooking eggs to order and the plancha for pancakes.

The two sides of the Athanor suite are set for mise en place. One side is also used for garnish and the other for the cooking of meat and fish. These comprise a mixture of twin-zone induction units for pan cooking, PlaqueAthanor cook-plates for either pan cooking or direct cooking, a 6KW chaufont/multi-cooker for refreshing and cooking vegetables and pasta, and a gas-fired lava stone chargrill for meat or fish. Set below the top is an additional set of hot holding drawers and a classic cast iron-lined roasting and service oven.

tom covers for the induction hobs were also purchased. "The brigade understands the investment that has been made in the kitchen. They respect the equipment and want to look after it," says Klaner.

With temperatures in the kitchen previously hitting 50ºC, another advantage of the Athanor is the reduction in heat.

"We only use the induction when we need it, so we have decreased our energy usage and bills; or rather, our bills are the same now that energy prices have increased," he says.

The only outward sign of the new kitchen are automatic twin doors (2) designed by the hotel's interior designer and Humble Arnold. "The doors had to be designed in-keeping with the interior of the hotel, but have made a

massive difference to the front of house and kitchen dynamic," says Klaner.

As the chefs go through these doors they immediately pass a small, separate pastry kitchen(3) with the usual accoutrements of this section, including Pacojets(4) and Hobart mixers (5). This small space is used for the preparation of desserts and afternoon tea.

e top-right corner of the kitchen, the pot-wash area, includes a Winterhalter UF Series warewasher(6), and refrigeration across the kitchen is supplied by Foster Refrigerator(7).

In the centre of the hot kitchen the sections are organised around the Athanor island suite (1), with a hot prep area (8) a bespoke breakfast section(9) and a cold prep and bulk cooking (11), that includes a Rational SelfCookingCentre and a Hobart ELRO bratt pan and boiler.

The basement kitchen

The Winter Garden kitchen produces an average of 200 plated breakfasts, 80 lunches and 80 dinners a day, Monday to Friday. At the weekend it supplies a hot buffet breakfast for more than 200 residents.

Afternoon tea is produced in both the Winter Garden kitchen and the basement kitchen, and 120 afternoon teas are served a day at weekends. The basement kitchen is the larder kitchen for banqueting and the main pastry kitchen for the whole hotel except the Winter Garden restaurant.

Suppliers

Grande Cuisine and Athanorwww.grandecuisine.co.uk

Pacojetwww.pacojet.com

Hobartwww.hobartuk.com/food-prep/mixers

Foster Refrigeratorwww.fosterrefrigerator.com

Winterhalterwww.winterhalter.com

Rationalwww.rational-online.com

ELROwww.hobartuk.com/cooking/elro-range

Humble Arnold Associateswww.humblearnold.com

Berkeley Projectswww.berkeleyprojects.co.uk

Continue reading

You need to be a premium member to view this. Subscribe from just 99p per week.

Already subscribed? Log In